In the world of cryogenics, where temperatures can reach -452°F (-269°C), mechanical insulation often isn’t suitable to keep liquified gases cold enough for storage, transfer, or use. Without sufficient insulation, liquids boil off, reducing the liquid quality and creating a wasted product. Instead, most users deploy piping that utilizes super-insulation to minimize heat transfer. In a high vacuum environment, molecular activity is reduced to almost 0, preventing heat from being transferred between surfaces. This type of technology is often called either:

- Vacuum Insulated Pipe, or “VIP” for short

- Vacuum Jacketed Pipe, or simply “VJ Pipe”

But which is correct? Are they the same or are there subtle differences? What do the cryo-insiders say?

As the name implies, this naming convention focuses on the insulating properties of the system. In VIP systems, a high vacuum is pulled between the inside pipe that carries the cryogenic liquid (called the carrier pipe), and the outer pipe (called the jacket) creating an annular space without the capacity to transfer heat via conduction or convection. The carrier pipe is then wrapped in special foil/paper, called Multi-Layer Insulation (MLI), to significantly reduce heat transfer through radiation. The resulting system has almost no heat transfer and can transport cryogenic liquids over long distances or keep them in their liquid form for extended periods.

Vacuum Jacketed Pipe - VJ Pipe

In contrast with Vacuum Insulated Pipe, the name Vacuum Jacketed Pipe focuses on the construction of the piping system. Here, the “Jacket” is the key feature. The “Jacket” is most often made of stainless steel that matches the carrier pipe construction material. This helps prevent corrosion and eliminate dissimilar welds while providing strength for structural stability and vacuum retention. Don’t let the name fool you, this piping system also uses vacuum and MLI to minimize conduction, convection, and radiation heat transfer.

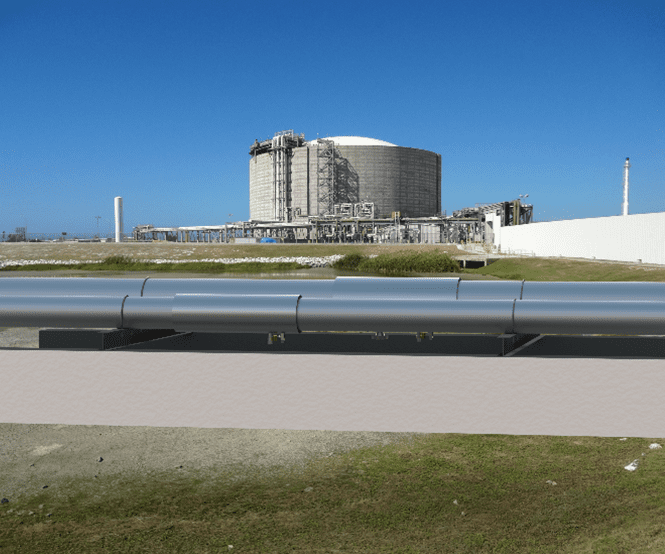

In LNG (Liquified Natural Gas) piping systems, the jacket pipe is often made thicker, capable of withstanding the full pressure and temperature of the cryogenic fluid so that it can be contained in the unlikely event the carrier pipe fails. This practice is commonly known as dual containment or secondary containment and is especially important when LNG facilities are located near business and residential communities. The practice of dual containment helps to significantly reduce the risk of release of LNG or gaseous natural gas and allows facilities to pass regulatory and environmental impact approval.

So which is it, Vacuum Insulated or Jacketed Pipe? Officially, Vacuum Insulated Pipe (VIP), is more common, showing up on articles, websites, and in official industry publications. However, when people in the industry talk about this type of piping, they almost always say, VJ pipe. Here is our recommendation, if you’re looking for information, use Vacuum Insulated Pipe. If you’re talking to an engineer at NASA or freezer farm manager at big pharma, make sure you call it VJ Pipe.

CryoWorks Has A Vacuum Insulated Piping Solution For You

Regardless of which term you use, CryoWorks has a solution that is right for you. Our VIP is the preferred method for transferring cryogenic liquids and is unmatched in safety, reliability, and cost-effectiveness. CryoWorks provides best in industry delivery and service with relentless dedication to:

- Complex System Design & Engineering

- Expert Project Management

- Experienced Sales Staff with Component and System Expertise

- Easier & faster installation

- Shop fabricated and tested to order

Our products are highly engineered and rigorously proven:

- +20 years life expectancy

- Low to no maintenance costs for the life of the system

- Reduction of Boil-Off Gas (BOG) and lost commodity cost

- Longer piping runs with fewer expansion loops

- Smaller diameter compared to conventional insulation, taking up less pipe rack space

- Built to customer specifications including: ASME B31.3, ASME B31.12, and NFPA 59A

We Offer Rigid Piping and Flexible Vacuum Insulated Solutions:

- Rigid engineered pipe with internal or external expansion joints

- CryoLinks® Pre-Engineered VIP

- Flexible VIP hoses

- Full containment piping

Application:

LNG VIP Bunkering Application

LNG VIP Bunkering Application