CRYOWorks is now under the Crane umbrella of brands

CRYOWorks Inc. is set to celebrate its 15th anniversary in August 2024 and has recently joined the Crane family of brands, sporting a new logo. Established in 2009 by Tim

CryoWorks offers three standard design options, and these can be supplied in custom sizes, pressures, and single to multi-outlet units. The three standard design options are Gravity Feed Phase Separators (GFPS), Adjustable Pressure Phase Separators (APPS), and Vacuum Insulated Reservoir. CryoWorks Phase Separators are versatile in design. Requested changes, customization, specific requirements, and system redundancy are all available.

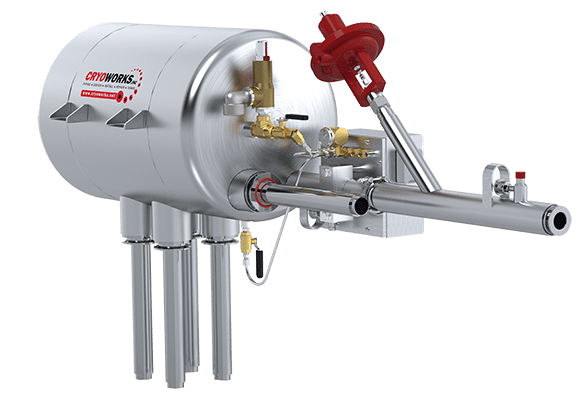

A CryoWorks Gravity-Fed Phase Separator (GFPS) is designed to maintain high-quality liquid for on-demand withdrawal at atmospheric pressure. GFPS units can supply liquid up to 25°F (14°C) colder than a bulk storage tank temperature at 50 PSI.

An inlet control valve proportionally controls the incoming flow from the higher pressure liquid nitrogen source to maintain the set liquid level. The headspace of the GFPS is open to the atmosphere to ensure no pressure build-up inside the phase separator. Low pressure saturated liquid can then be gravity-fed from the GFPS to your use points.

A CryoWorks GFPS can be used with closed loop systems utilizing supply and return lines. Ideal for applications requiring gravity-fed liquid such as Molecular Beam Epitaxy (MBE), Thermal Vacuum Chambers (TVAC) and Food and Beverage (Ice Cream / Bottle Dosing & Inerting).

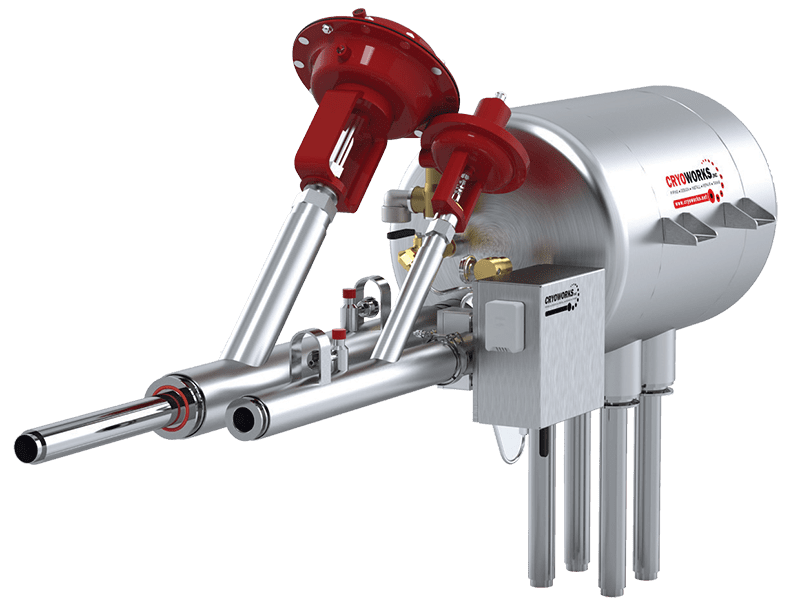

A CryoWorks Adjustable Pressure Phase Separator (APPS) is designed to maintain high-quality liquid for on-demand withdrawal at a customer-specified and adjusted pressure.

An inlet control valve proportionally controls the incoming flow from the higher pressure liquid nitrogen source to keep the phase separator full. The vent control valve proportionally controls the gaseous nitrogen venting from the phase separator to maintain the set head pressure.

A CryoWorks APPS can be used on any application that requires high-quality liquid delivery at a pressure that is less than the bulk tank or branch line pressure. Ideal applications include Environmental Test Chambers and Thermal Vacuum Chambers. These either have valves or controls that cannot handle the full pressure from the bulk tank, or would benefit from colder/ lower pressure liquid nitrogen.

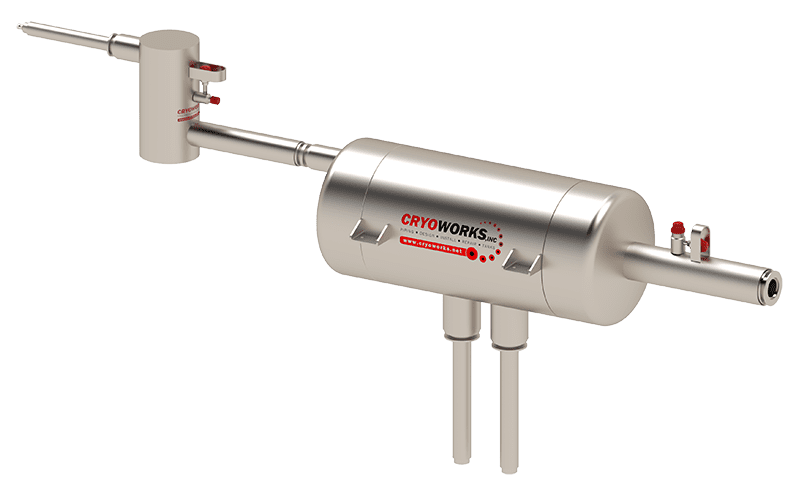

A CryoWorks Vacuum Insulated Reservoir is designed to maintain high-quality liquid for on-demand withdrawal at line pressure. The Vacuum Insulated Reservoir consists of a reservoir and keepfull vent device. Reservoirs, also known as accumulators, create an area for liquid/gas phase separation to occur. When coupled with the keepfull vent device, the gas rises to the top to be vented, and high-quality liquid is dispensed from the bottom. The reservoir generates a reserve of liquid that helps eliminate the issues associated with two-phase flow coming from upstream supply lines. Two-phase flow can be caused by undersized supply lines, incorrect sloping, and sometimes other existing system inefficiencies. A CryoWorks Vacuum Insulated Reservoir can be used on any application that requires high-quality liquid delivery at a pressure that is equal to the bulk tank or branch line pressure.

A CryoWorks Subcooler is designed to maintain high-quality subcooled liquid for on-demand withdrawal at line pressure. Improve the quality of your cryogenic fluid using CryoWorks Subcoolers. Subcoolers lower the temperature of your cryogen below the line pressure boiling point. This subsequently eliminates gas downstream of the subcooler. By removing the heat from the cryogen by using a CryoWorks subcooler, you reduce the friction pressure drop by maintaining single-phase flow for a distance after exiting the subcooler. This allows you to transport over longer lengths of piping or reduce piping sizes, all while delivering single-phase cryogen to your critical application.

CRYOWorks Inc. is set to celebrate its 15th anniversary in August 2024 and has recently joined the Crane family of brands, sporting a new logo. Established in 2009 by Tim

From long-distance trucking, inner-city transportation, and even fueling the rockets taking humans to Mars, Hydrogen is emerging as a premier solution to decarbonize industry. As the world transitions to cleaner

CRYOWorks, Inc.

3309 Grapevine Street

Jurupa Valley, CA 91752

Phone: 951-360-0920

Fax: 951-848-9503

Email: sales@CryoWorks.net

Follow us on

® 2022 CRYOWorks, Inc. All Rights Reserved. The site makes use of necessary cookies only. Continued use of this site indicates your consent.

Privacy Policy | Terms and Conditions | Accessibility Policy | Careers