Molecular Beam Epitaxy

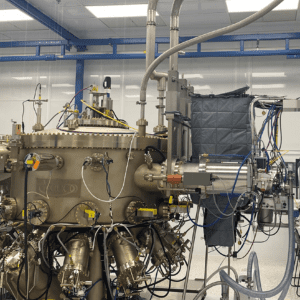

Molecular Beam Epitaxy, otherwise known as MBE, is a material deposition technology in which molecules are evaporated onto a wafer surface, stacking layer by layer to form high quality crystal films. This process requires low pressure, low contamination and takes place in an ultrahigh vacuum (UHV) chamber.

Cryogenic shrouds, or cryopanels, are essential to the UHV chamber. Within the vacuum chamber there are two cryopanels that may be filled with LN2, the growth cryopanel and the source cryopanel. The growth cryopanel surrounds the wafer holder and helps cryotrap contaminants near the wafer. The source cryopanel has openings for each material source, allowing molecules to pass through and reach the substrate. These cryogenic shrouds provide thermal isolation for the material sources, allowing the temperatures to be controlled independently and ensuring consistent evaporation of molecules.

It is important to note that the process for MBE requires the cryopanels to be continuously wetted with LN2 closed loop circulation with a constant flow. The closed loop process features gravity fed LN2 from a liquid/vapor phase separator. Feed and Return Lines connect from the bottom of the Phase Separator and run down to the various MBE connections via vacuum insulated flexible piping. A feed line supplies LN2 into the MBE, while a return line brings the mixture of LN2/GN2 back to the separator where gas exits out of the separator vent and liquid circles back in the separator for reuse. The bayonets that are in each of the phase separator lines are designed to only allow flow from a separator into a supply line and not into the return line.

The result of the MBE process is a compound semiconductor thin film on the wafer. The wafer will then undergo processing in a fabrication facility, often resulting in an integrated circuit or microchip, commonly found in computers and cell phones. MBE systems use a lot of liquid nitrogen and it is recommended to have one phase separator per MBE. One pair of feed/return lines are normally the minimum for any MBE but large production systems can have up to four pairs of feed/return lines on a system. Some MBE manufacturers offer vacuum insulated connections (TAL or close tolerance bayonets) to the MBE to reduce icing and heat gain.

Some common MBE manufacturers are, Veeco / Varian / Applied EPI, Riber / Thermo VG Semicon, Scienta Omicron, SVTA, and DCA.

CryoWorks offers assorted system options to improve the performance of your MBE:

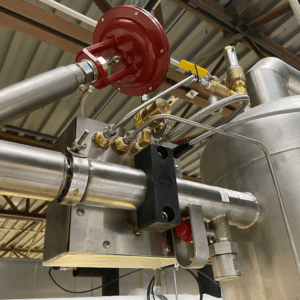

Phase Separators: CryoWorks Gravity Feed Phase Separators are the ideal solution for MBE applications that require saturated, low temperature, high quality liquid nitrogen for its cryopanels or cryoshrouds. Our Phase Separators are versatile in design and can accommodate changes, customization, specific requirements, and system redundancy. CryoWorks offers both Gravity Feed Phase Separators (GFPS) and Adjustable Pressure Phase Separators (APPS).

Vacuum Insulated Piping (VIP): CryoWorks offers both rigid and flexible vacuum insulated piping. Our Vacuum Insulated Flexible Lines are lightweight, extremely flexible, and thermally efficient. Icing problems attributed to the high volume of liquid nitrogen in MBE are reduced and Foreign Object Debris/Damage (FOD) safety concerns are minimized with our VIP lines. They provide faster, more consistent liquid delivery with a safe to touch jacket. CryoWorks offers both Static and Dynamic Vacuum type systems.

Valves: CryoWorks Valve line offers a broad range of vacuum insulated and non-insulated cryogenic valves that exceed highest industry standards. Our valves ensure reduction of production loss by eliminating the potential for the valve to ice up with no fluid flow.

Bayonets: CryoWorks bayonet connections consist of a male and female connector that can easily be installed without any field welding or unique training. The tight-fitting male and female bayonet design provides a long heat path from the outer jacket to the inner pipe, this creates a low heat leak connection. CryoWorks offers close tolerance fit bayonets as well as dissimilar metal tip bayonet types. Our bayonet connections also have a low-profile flange to simplify installation allowing pipes to slide through hangers and supports easily. This low-profile also decreases core hole diameters and required sealant.