Author: Matt Miller, Director of Sales – Commercial Division

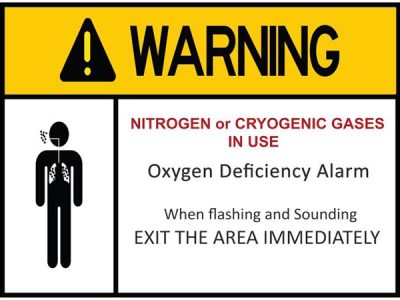

The safety of a cryogenic distribution system goes beyond piping components such as pressure relief devices and shut-off Valves; it also includes components such as oxygen deficiency monitors. Oxygen Monitors play a critical role in cryogenic piping systems due to the risk of oxygen depletion in confined areas such as laboratories, hallways, cleanrooms, and tank enclosures. With a properly designed oxygen monitoring system, you can ensure that these areas in your facility are being monitored and will alert personnel if a hazard is present.

When working with inert cryogenic fluids such as LN2, LAR, or LHe, there is a risk of oxygen depletion in the event of a sudden release of the fluid. All these fluids are colorless and odorless and have rapid expansion ratios when changing from liquid to gaseous. While none of these gases are dangerous in low concentrations, they can cause asphyxiation when they deplete the oxygen levels due to rapid expansion ratios.

Alert Workers Before It Becomes a Hazard:

Properly designed oxygen monitoring systems often include remote displays, horn and strobe lights, multiple oxygen deficiency monitors, central controllers, signage, emergency shut-off valves, exhaust vents, and employee training. Oxygen deficiency monitors monitor oxygen levels in confined spaces and alarm if the level drops below the preset threshold set by the manufacturer. All these components combined allow an automated system to visually and audibly communicate a potential hazard to personnel avoiding injury or death due to oxygen depletion. In addition to alerting those onsite of the danger, many oxygen monitoring systems can communicate with BMS systems, which can help communicate with personnel offsite.

CryoWorks has a full line of oxygen monitors ready for your system! Order our available options here on Shop.CryoWorks.Net and protect your workers and production today!